Weld Geomembrane on Construction Site: The Things You must Know

Weld Geomembrane on Construction Site: The Things You must Know

The welding process of the hot welding machine is divided into: adjusting the pressure, setting the temperature, setting the speed, welding seam overlap inspection, loading the film into the machine, and initiating the motor.

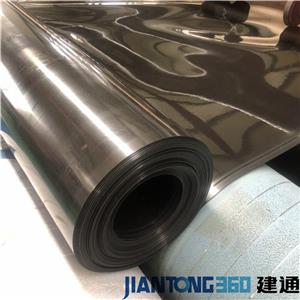

There should be no oil dirt or dust at the joints. The overlapping section of the HDPE impermeable membrane should not be debris, dew, moisture, etc. When there are debris, it is necessary to clean it up before welding.

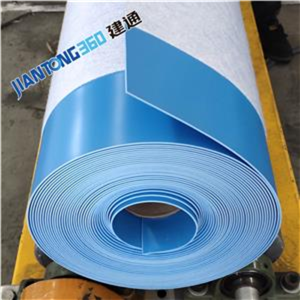

The waterproof board needs to be regular and beautiful in the welding seam, and must not have sliding welding or jumping away.

At the beginning of welding every day, a sample of 0.9mm*0.3mm should generally be welded on site, with a lap width of not less than 10cm, and peeling and shearing should be stopped at the site. After the sample is qualified, it can be adjusted at the time.

During the welding process, the hot wedge welding machine needs to pay attention to the operation of the welding machine at any time. It is necessary to stop fine-tuning the speed and temperature according to the actual situation on site.