Some Effective Welding Methods of Geomembrane for Landfills

Some Effective Welding Methods of Geomembrane for Landfills

A lot of clients often ask about the welding of geomembrane for landfills and would like to know is there any matters needing attention.

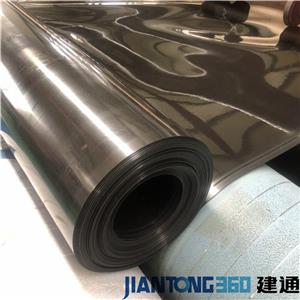

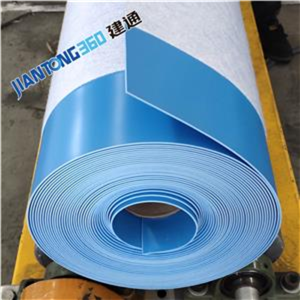

The anti-permeability of geomembrane mainly depends on the anti-permeability of plastic film, and the quality of its anti-permeability depends on its welding process. The proper control of the welding industry will make the geomembrane play a greater role:

In case of welding at a slope, the length of the weld seam should extend along the slope and cannot be traversed.

The welding machine should be maintained regularly, and the residue in the welding machine equipment should be cleaned frequently.

A welding supervisor should supervise the welding operation.

The surface of the geomembrane should be cleared without grease, moisture, dust, garbage and other debris.

If the welding is done at night, there should be sufficient lighting.

When the ambient temperature and adverse weather conditions seriously affect the welding of geomembrane, the installation should be stopped.

Welding a complete geomembrane will be more conducive to work, but whether it is production welding or experimental welding, it is necessary to maintain the welding temperature, speed, and pressure of the clamping rod, so that the welding can achieve better results.