In-depth Analysis of the Core Differences and Applications of HDPE and LDPE

In-depth Analysis of the Core Differences and Applications of HDPE and LDPE

[Website Name/Section] - [Date] Plastic products are ubiquitous in our daily lives, from supermarket shopping bags to home plumbing. Among them, **polyethylene (PE)** is one of the world's largest-produced and most widely used synthetic resins. Within the polyethylene family, **high-density polyethylene (HDPE) and low-density polyethylene (LDPE)** are the two most frequently mentioned, yet most easily confused, "members."

Although they are chemically identical, both polymerized from ethylene monomers, differences in their molecular structures lead to vastly different physical properties, application scenarios, and processing technologies. This article will provide an in-depth analysis of the core differences between these two "plastic brothers," helping you make more informed decisions when purchasing and applying them.

I. The Source of the Core Differences: Molecular Structure and Production Process

To understand the differences between HDPE and LDPE, we must delve into the microscopic world and examine how their molecular chains are arranged.

● HDPE (High-Density Polyethylene) – “A Disciplined Army”

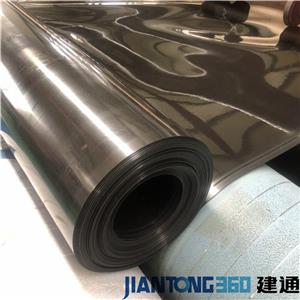

HDPE is polymerized under low pressure through catalytic polymerization, hence it is also called “low-pressure polyethylene.” Its molecular chains are almost linear with very few branches. This orderly arrangement allows the molecular chains to pack tightly together, resulting in extremely high crystallinity (typically 80%-90%). Therefore, its density is relatively high, usually between 0.941-0.965 g/cm³.

● LDPE (Low-Density Polyethylene) – “A Lush Tree”

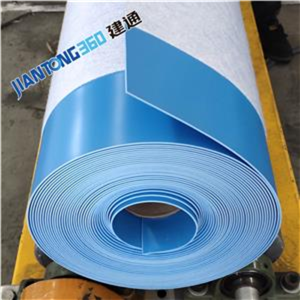

LDPE is a product polymerized under high temperature and pressure, hence it is also called “high-pressure polyethylene.” Its molecular chains have numerous long and short branches. These branches, like tree branches, hinder the tight packing of the molecular chains, resulting in a relatively loose structure and lower crystallinity (approximately 50%-60%). Therefore, its density is relatively low, usually between 0.910-0.925 g/cm³.

II. Performance Comparison: A Battle of Rigidity and Flexibility

Based on the structural differences mentioned above, HDPE and LDPE exhibit drastically different macroscopic properties.

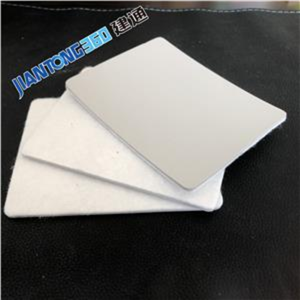

HDPE is renowned for its superior rigidity and strength. It has high hardness, high tensile strength, and excellent chemical resistance, resisting the erosion of strong acids, strong alkalis, and organic solvents. Furthermore, HDPE has better heat resistance, with a melting point typically between 125-135℃, and its barrier properties against water vapor and gases are superior to LDPE. However, its disadvantage is lower transparency, typically appearing as a milky white, semi-transparent substance.

LDPE, on the other hand, excels in flexibility and ductility. It has a soft, smooth feel, excellent elongation and impact resistance, and maintains good flexibility, especially at low temperatures. LDPE has higher transparency and excellent electrical insulation and permeability. Its heat-sealing properties are excellent, making it easy to process and mold, but its heat resistance is relatively low, with a melting point typically between 105-115℃.

III. Application Scenarios: Each Showing Its Unique Strength, Making the Most of Its Properties

Due to their different performance characteristics, HDPE and LDPE have clearly defined roles in practical applications, almost "keeping to themselves."

1. HDPE: The "Tough Guy" of Industrial and Rigid Packaging

With its high strength, high hardness, and excellent chemical corrosion resistance, HDPE is commonly used in applications requiring load-bearing capacity, pressure resistance, and corrosion resistance.

● Rigid Containers: This is HDPE's largest application market, including milk bottles, juice bottles, detergent bottles, cosmetic bottles, medicine bottles, and large chemical drums.

● Piping Systems: In construction and municipal engineering, HDPE is widely used to manufacture drinking water pipes, sewage pipes, gas pipes, and cable sheaths, offering long service life and corrosion resistance.

● Daily Necessities and Industrial Products: Garbage cans, turnover boxes, pallets, cutting boards, chemical storage tanks, and outdoor furniture, etc.

● Film Products: Shopping bags, merchandise bags, and garbage bags requiring a certain degree of rigidity are also often made of HDPE.

2. LDPE: The "Contortionist" of Flexible Packaging and Special Functions

With its exceptional flexibility, stretch, and transparency, LDPE is irreplaceable in flexible packaging and applications requiring excellent sealing.

● Films and Packaging: This is LDPE's main battleground. Examples include food wrap, resealable bags, bread bags, clothing bags, agricultural mulch films, and bubble wrap.

● Flexible Containers: Widely used for squeeze bottles of shampoo, shower gel, honey, and ketchup due to its excellent flexibility.

● Special Applications: Insulation layers for wires and cables, waterproof coatings for the inner walls of paper cups/milk cartons, medical infusion bags, gloves, and coating applications.

IV. Environmental Protection and Recycling: Sorting is Key

In today's increasingly environmentally conscious world, understanding the recycling symbols for both is crucial.

● Recycling Symbols: HDPE's recycling code is "2" (usually a triangle), while LDPE's recycling code is **"4"**.

● Recycling: Both are recyclable plastics, but must be sorted. Recycled HDPE, due to its high strength, is often used to make park benches, drainage pipes, or new packaging containers; while recycled LDPE is mostly processed into garbage bags, films, or composite packaging materials.

V. Summary and Recommendations

Although HDPE and LDPE both belong to the polyethylene family, their different molecular structures (linear vs. branched) lead to differences in density and crystallinity, thus determining their applications.

● If you need to manufacture rigid products that are load-bearing, pressure-resistant, and corrosion-resistant (such as water pipes and oil drums), or packaging with high barrier properties, please choose HDPE first.

● If you need to manufacture flexible, transparent, and easily foldable packaging (such as cling film and shopping bags), or products that require low-temperature resistance and easy heat sealing, please choose LDPE first.

Understanding these differences can not only help companies optimize material selection and reduce costs and increase efficiency, but also help ordinary consumers better understand materials in their daily lives and become more informed environmental practitioners.