Building a Green Defense Line: Key Applications and Advantages of HDPE Geomembrane in Wastewater Treatment Ponds

Title: Building a Green Defense Line: Key Applications and Advantages of HDPE Geomembrane in Wastewater Treatment Ponds

Publication Date: January 4, 2026

Source: Materials and Environmental Engineering Information Network

[Introduction] With increasingly stringent environmental regulations and the growing awareness of sustainable development, seepage prevention and corrosion protection of wastewater treatment facilities have become paramount in engineering construction. Among numerous seepage prevention materials, high-density polyethylene (HDPE) geomembrane, with its superior performance, has become the "standard configuration" for seepage prevention projects in wastewater treatment ponds. This article will provide an in-depth analysis of the specific applications, core advantages, and key construction points of HDPE geomembrane in wastewater treatment ponds.

I. Why is HDPE Geomembrane indispensable for wastewater treatment ponds?

Wastewater treatment ponds (including equalization ponds, anaerobic ponds, aerobic ponds, sedimentation ponds, emergency ponds, etc.) store wastewater containing acids, alkalis, salts, and various organic pollutants year-round. Once leakage occurs, it will cause irreversible pollution to groundwater and surrounding soil.

Traditional concrete structures, while possessing some seepage prevention capabilities, suffer from drawbacks such as high cost, long construction periods, and poor crack resistance (prone to cracking due to geological settlement). In contrast, HDPE geomembrane, as a flexible waterproof barrier material, perfectly solves these problems.

II. Four Core Advantages of HDPE Geomembrane

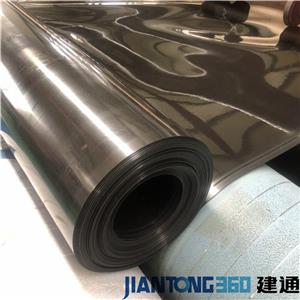

1. Ultimate Seepage Prevention Performance

HDPE geomembrane has an extremely low permeability coefficient (as low as 1×10⁻¹³ cm/s), nearly "zero permeability." It effectively blocks the seepage of harmful substances in wastewater, protecting groundwater resources and preventing groundwater backflow from affecting the normal operation of treatment ponds.

2. Excellent Chemical Corrosion Resistance

Wastewater treatment environments are complex, often accompanied by acid and alkali corrosion. HDPE geomembrane exhibits excellent resistance to more than 80 chemical media, maintaining structural stability over long periods without aging or decomposition, regardless of whether the wastewater is acidic or alkaline.

3. Excellent Resistance to Deformation and Settlement

Unlike rigid concrete, HDPE geomembrane has extremely high elongation at break (typically ≥700%). This means it can adapt well to uneven settlement and thermal expansion and contraction of the foundation, and will not crack due to minor deformations like concrete, thus ensuring the integrity of the impermeable layer.

4. Ultra-Long Service Life and Economic Efficiency

By adding UV stabilizers and antioxidants, HDPE geomembrane can have a service life of over 50 years under normal conditions. At the same time, its construction is convenient (no need to wait for a setting period like concrete), and its transportation and laying are rapid, significantly reducing the overall cost of the project and subsequent maintenance costs.

III. Specific Application Scenarios

HDPE geomembrane is widely used in sewage treatment plants and various industrial wastewater treatment facilities:

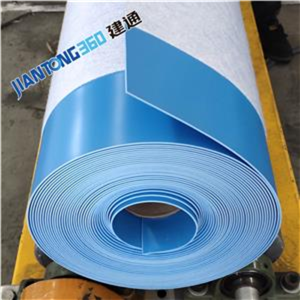

● Main Structure Impermeability: Used for impermeability of the bottom and slopes of equalization tanks, biological reaction tanks (anaerobic/aerobic tanks), sedimentation tanks, and sludge thickening tanks.

● Emergency Protection: Serves as a last line of defense in emergency response tanks to prevent leakage of high-concentration wastewater.

● Transportation Channels: Used for lining open channels for sewage transportation to prevent leakage during the transportation process.

IV. Construction Key Points and Precautions

To ensure seepage prevention, the construction of HDPE geomembrane must be rigorous and standardized:

● Base Treatment: This is the most crucial step. The base layer (soil or concrete) must be firm, flat, and free of sharp objects (such as stones, tree roots, or rebar ends) to prevent punctures to the membrane. Corners should be rounded.

● Laying and Welding: Sufficient expansion allowance should be allowed during laying to avoid over-tightening or wrinkling. Welding is usually done using a hot-melt welding machine, with temperature and speed carefully controlled to ensure continuous, uniform welds without any gaps or incomplete welds.

● Inspection and Protection: Strict air pressure and vacuum testing is required after welding. A protective layer (such as geotextile, concrete slab, or backfill soil) is usually laid on top of the geomembrane to prevent mechanical damage during subsequent construction or operation.

V. Conclusion

HDPE geomembrane is not only a "protective garment" for sewage treatment ponds but also a "green guardian" protecting the ecological environment. With continuous advancements in materials science, thicker, stronger, and more weather-resistant HDPE geomembrane products will continue to emerge, providing a more robust and reliable guarantee for global water resource protection and environmental governance projects.

[About This Information] This article aims to popularize knowledge about the application of HDPE geomembranes in environmental engineering. For specific product selection or construction technical support, it is recommended to consult a professional geosynthetic material supplier or engineering contractor.