In-depth comparison of PVC waterproof membrane and TPO waterproof membrane: Which will be the "hidden champion" of future building waterproofing?

I. Material Characteristics: A Battle Between Weather Resistance and Flexibility

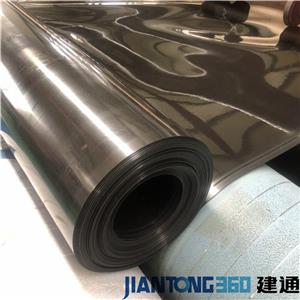

PVC waterproof membrane (polyvinyl chloride waterproof membrane) is a thermoplastic waterproof material made primarily of polyvinyl chloride resin, supplemented with plasticizers, stabilizers, and other chemical additives. It is renowned for its excellent aging resistance, high tensile strength, and good low-temperature flexibility (remaining flexible even at -20℃). Furthermore, PVC materials possess excellent dimensional stability and chemical corrosion resistance, making them particularly suitable for industrial plants and underground projects in complex acid and alkaline environments.

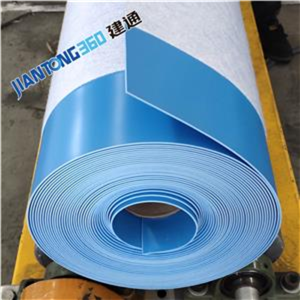

In contrast, TPO waterproof membrane (thermoplastic polyolefin waterproof membrane) represents a higher level of environmental protection and weather resistance. TPO material is made from ethylene resin base material using advanced polymerization technology. It not only possesses the high strength of PVC but also boasts excellent UV resistance and high-temperature stability. TPO surfaces are typically white with high reflectivity, effectively reducing roof temperature and saving building cooling energy consumption, making it an ideal choice for green and low-carbon buildings.

II. Construction and Connection: The Common Language of Hot Air Welding

In terms of construction technology, both PVC and TPO demonstrate the superiority of polymer materials. Both support various construction methods, including loose-laying, mechanical fixing, and full-adhesion, adapting to different substrate environments.

Most importantly, both utilize hot air welding technology for joint treatment. Using a handheld hot air welding gun, the overlapping areas of the membrane are fused together to form a sealed layer integrated with the base material, with weld strength even exceeding that of the membrane itself. This construction method completely solves the problem of leaks at joints in traditional waterproofing materials, significantly improving the reliability and durability of the waterproofing system.

III. Environmental Protection and Sustainability: TPO Leads the Future Trend

With increasingly stringent national environmental protection requirements, the environmental friendliness of materials has become a crucial consideration.

● PVC membrane: Although possessing excellent performance, its production process may involve plasticizer migration, posing a risk of aging under extreme high temperatures.

● TPO membrane: As a chlorine-free and non-toxic environmentally friendly material, TPO does not release harmful gases during production and construction and is 100% recyclable. Currently, domestic companies such as Sinopec-SK Petrochemical and Oriental Yuhong have achieved breakthroughs in the localization of TPO special materials, breaking the foreign monopoly and promoting the rapid popularization of TPO materials in large-scale infrastructure, municipal engineering, and new energy vehicle factories (such as GAC Honda's pure electric plant).

IV. Application Scenarios and Market Outlook

Currently, PVC waterproof membranes, with their mature supply chain and high cost-effectiveness, still occupy an important position in the fields of basement, tunnel, water conservancy projects, and water tank seepage prevention, with a service life of up to 25 years for roofs and over 50 years underground.

Meanwhile, TPO waterproof membranes, with their superior performance in single-layer roofing systems, are rapidly capturing the high-end market in large industrial plants, public buildings (such as convention centers and sports centers), and photovoltaic roofs. Data shows that the annual growth rate of TPO products is as high as 15%, making it a major direction for the future development of waterproof materials.

【Conclusion】 Whether choosing the mature PVC system or embracing the cutting-edge TPO technology, the core lies in matching the actual needs of the project. As a professional waterproofing solutions provider, we are committed to providing safe, durable, and environmentally friendly waterproofing protection for all types of civil buildings, municipal projects, and transportation infrastructure, enabling every building to safely withstand the test of wind and rain.