The laying technology of the geotextile

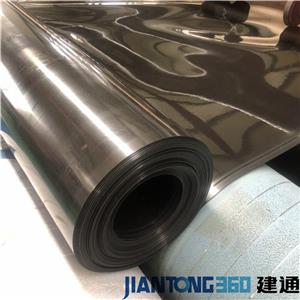

1. Store, transport, and dispose of geotextiles

Geotextile rolls should avoid damage before installation and deployment. Geotextile rolls should be stacked in a flat place, with a height of no more than four rolls, and the identification sheet of the rolls can be seen. Geotextile coils must be covered with opaque material to prevent UV aging. During storage, keep the label and the data complete. During transportation (including transportation from the site of material storage to work). Geotextile rolls with physical damage must be repaired. Seriously worn geotextiles should not be used. Any geotextile exposed to a leaking chemical reagent is not permitted for use in the Works.

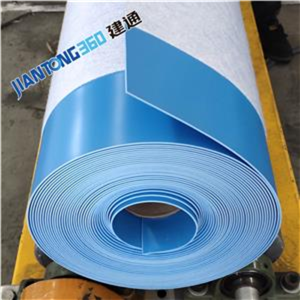

2. The laying method of geotextile

2.1 Use manual rolling; the cloth surface shall be flat and have appropriate deformation allowance.

2.2 Suture of geotextile: All sutures must be performed continuously (e. g., spot seams are not allowed). Before the overlap, the geotextile must overlap at least 150mm. The minimum needle distance is at least 25mm (the edge of the exposed material). The sewn geotextile joint includes 1 line and line lock chain joint method. The thread for suture shall be resin material with minimum tension exceeding 60N and have chemical corrosion and UV resistance comparable to or beyond the geotextile. Any "missed needle" on sewn geotextiles must be resewn in the affected area. Corresponding measures must be taken to avoid entering the soil, particulate matter or foreign material into the geotextile layer after installation. The lap of cloth can be divided into natural lap, seam connection or welding according to the terrain and use function.Basic requirements for geotextile laying

3.1 The joints shall intersect the slope line; where the distance may be stressed, the horizontal joints shall be greater than 1.5m.

3.2 On the slope, anchor one end of the geotextile, and then lower the roll must slope to ensure that the geotextile remains tight.

3.3 All geotextiles shall be pressed with sand bags, which shall be used during laying and retained to lay the upper layer of material.

4.Technical requirements for geotextile laying

4.1 Basic level inspection: check whether the basic level is smooth and solid. If there is any foreign matter, it should be properly handled.

4.2 Test shop: according to the site situation, determine the size of geotextile, make test shop after cutting, and the cutting size should be accurate.

4.3 Check whether the width of the Sarah is appropriate, and the lap place should be smooth and moderately elastic.

4.4 Positioning: bond the lap parts of the two geotextiles with a hot air gun, and the spacing between the bonding points should be appropriate.

4.5 The suture line should be straight and the stitches should be uniform.

4.6 After suture, check whether the geotextile is smooth and whether there are defects.

4.7 If there is any inconsistency, it should be repaired in time.

5. Self-inspection and repair

5.1 All geotextile sheets and joints must be inspected. Defective geotextile sheets and sutures must be clearly marked on them and repaired.

5.2 The worn geotextile must be repaired by laying and hot connecting the small pieces of geotextile, which should be at least 200mm longer in all directions than the edge of the defect. Thermal connections must be strictly controlled to ensure that the geotextile patches and geotextiles have no damage to the geotextiles.

5.3 Before the end of laying every day, make visual inspection of all the geotextile surfaces laid on the day to determine that all the damaged places have been marked and repaired immediately, to determine that there is no foreign substances that may cause damage to the laid surface, such as fine needles, small nails, and the foreign substances that may cause damage, such as fine needles, small nails, etc.

5.4 The patch material used to fill the holes or cracks should be consistent with the geotextile.

6, geotextile installation and construction precautions

6.1 Geotextile can only be cut with geotextile knife (hook knife). If cutting in the site, special protection measures shall be taken for other materials to prevent unnecessary damage caused by the cutting of geotextile;

6.2 When laying the geotextile, it must be taken not to allow stones, large amounts of dust or water that may damage the geotextile, may block drainage channels or filters, or may bring difficulties to the following connection to enter the geotextile or geotextile;

6.3 After installation, all geotextile surfaces shall be visually inspected to identify all damaged landowners, marked and repaired to determine that the laid surface is free of foreign substances, such as foreign bodies such as broken needles

6.4 The connection of geotextile must follow the following provisions: under normal circumstances, there should be no horizontal connection on the slope (the connection must not cross the outline of the slope), except where repaired.

6.5 If stitched, the sutures shall be the same or more than the geotextile material, and the suture shall be held against chemical ultraviolet light. There should be obvious color difference between suture and geotextile for facilitate inspection.

6.7 Special attention is paid to the suture during installation to ensure that no soil or gravel in the gravel cover enters the middle of the geotextile.

7. Damage and repair of the geotextile

7.1 At the suture junction, resuture and ensure that the ends of the jumping part have been restitched.

7.2 In all areas, except for rock slopes, holes or tears must be repaired and stitched with geotextile patches of the same material.

7.3 At the bottom of the landfill, if the length of the crack exceeds 10% of the coil width, the damaged part will be cut off and the two parts will be connected.