Core Applications and Technological Advantages of HDPE Geomembrane in Tailings Treatment

[Industry News] Core Applications and Technological Advantages of HDPE Geomembrane in Tailings Treatment

Published: January 15, 2026

Under the dual background of modern mining development and environmental protection, tailings treatment has become a focus of industry attention. How to safely and efficiently store tailings and prevent harmful substances (such as heavy metals and acidic wastewater) from seeping into the soil and groundwater is a challenge that every mining company must face. In this process, HDPE geomembrane (high-density polyethylene geomembrane) has become an indispensable core material in tailings dam seepage prevention projects due to its superior performance.

This article will explore in depth the specific applications, technological advantages, and construction points of HDPE geomembrane in tailings treatment.

I. Why is HDPE geomembrane needed for tailings treatment?

Tailings dams (Tailings Pond/Reservoir) are dedicated sites used by mining companies to store tailings. Traditional tailings dams, if lacking effective seepage prevention measures, are prone to causing serious environmental pollution. According to relevant national environmental protection standards (such as GB 18599), especially for the disposal of Class II general industrial solid waste, high-standard seepage prevention systems must be adopted.

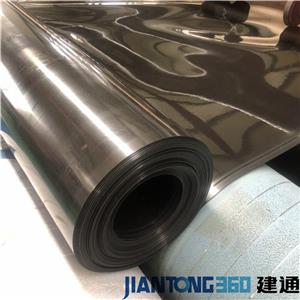

HDPE geomembrane, as a high-molecular synthetic material, has an extremely low permeability coefficient (reaching the level of 1×10⁻¹³ cm/s), effectively blocking the migration of liquids and gases. It is widely used in tailings dam bottom seepage prevention, heap leaching pond lining, red mud dumps, fly ash ponds, and wastewater regulating ponds, serving as a key barrier in building "green mines."

II. Core Advantages of HDPE Geomembrane in Tailings Treatment

1. Superior Seepage Prevention Performance: HDPE geomembrane is the core seepage prevention layer in tailings seepage prevention systems. Its seepage prevention function far surpasses that of compacted clay, effectively preventing the penetration of acids, alkalis, salts, and heavy metal ions in tailings water, protecting groundwater resources and the surrounding ecological environment.

2. Superior Chemical Stability: Tailings environments are complex and often contain acidic or alkaline substances. HDPE geomembranes can withstand acid and alkali corrosion within a pH range of 2-12, as well as the erosion of oils and various chemical solvents, maintaining stable performance even after long-term immersion in tailings water.

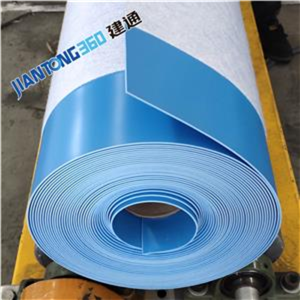

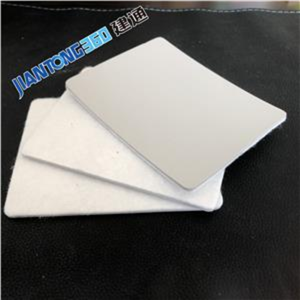

3. Excellent physical and mechanical properties: They possess high tensile strength and elongation at break, adapting to uneven settlement and creep deformation of tailings dam foundations, and are not prone to cracking. In particular, textured HDPE geomembranes, with their high surface friction coefficient, are suitable for tailings dam slope seepage prevention, effectively preventing membrane slippage.

4. UV resistance and aging resistance: High-quality HDPE geomembranes, fortified with carbon black and anti-aging additives, possess extremely strong UV resistance, ensuring a design service life of up to 30 years or even longer even after long-term exposure in open environments.

5. Convenient construction and cost-effectiveness: Compared to traditional clay seepage prevention, HDPE geomembranes are lightweight, easy to transport, and simple and quick to lay, significantly shortening the construction cycle. Simultaneously, their low maintenance costs save companies long-term operating expenses.

III. Typical Tailings Dam Seepage Prevention System Structural Design

In practical engineering, to ensure absolute safety, a composite seepage prevention lining system is usually adopted. A standard tailings dam seepage prevention structure typically includes, from top to bottom:

● Protective Layer: Usually made of non-woven geotextile (e.g., 600g or 800g), laid on top of the geomembrane to prevent tailings sand and gravel from puncturing the seepage prevention membrane, and also serves as drainage and filtration.

● Core Seepage Prevention Layer: A 1.5mm or 2.0mm thick HDPE geomembrane (selected according to project grade and design requirements), which is crucial for preventing leakage.

● Supporting/Drainage Layer: Can be a compacted clay layer or graded sand and gravel, used to provide a level foundation surface and collect any trace amounts of liquid that may seep through.

● Foundation Layer: The original soil layer that has been cleaned, leveled, and compacted.

IV. Construction Key Points and Quality Control

1. Foundation Treatment: Before laying, thoroughly remove tree roots, sharp stones, glass, and other debris from the base surface to ensure a flat and compacted foundation, preventing uneven stress on the geomembrane.

2. Standardized Laying and Welding: Use a professional hot-melt welding machine for welding, with an overlap width of no less than 10cm. Allow for allowance during construction to prevent thermal expansion and contraction caused by temperature changes, which could lead to membrane tension or wrinkling.

3. Finished Product Protection: Construction personnel should wear soft-soled shoes and are strictly prohibited from smoking or using open flames on the membrane. After laying, promptly cover and protect the membrane to prevent prolonged exposure to direct ultraviolet radiation.

4. Inspection and Acceptance: After welding, rigorous airtightness testing and destructive testing (peel and shear tests) must be conducted to ensure no missed welds or incomplete welds.

V. Conclusion

With increasingly stringent environmental regulations and enhanced corporate social responsibility, using high-quality HDPE geomembranes for tailings dam seepage prevention is not only a compliance requirement but also an inevitable choice for sustainable corporate development. It not only effectively isolates pollutants and prevents ecological disasters, but also helps enterprises reduce long-term environmental governance costs and legal risks.

Choosing high-quality HDPE geomembranes that meet national standards (such as GB/T 17643) and employing rigorous and scientific construction techniques is key to ensuring the safe, environmentally friendly, and long-term operation of tailings treatment projects.

Keywords: HDPE geomembrane, tailings treatment, tailings dam seepage prevention, high-density polyethylene geomembrane, mine seepage prevention, environmentally friendly seepage prevention, tailings dam lining, geomembrane construction, geomembrane manufacturers, textured geomembrane, composite geomembrane, tailings dam, heap leaching pond seepage prevention, groundwater protection, industrial solid waste treatment, geosynthetic materials.

Tags: #HDPEgeomembrane #tailingsdam #seepagepreventionproject #miningenvironmentalprotection #geomembraneconstruction #greenmine #highdensitypolyethylene #environmentalgovernance