Analysis of the key applications and performance advantages of non-woven geotextiles in landfills

With increasingly stringent national environmental protection requirements, landfills, as a crucial terminal for municipal solid waste disposal, are attracting significant attention for their engineering quality and environmental safety. Non-woven geotextiles, as a key geosynthetics material, play an irreplaceable role in this area thanks to their superior physical and chemical properties. This article will detail the diverse applications and core advantages of needle-punched non-woven fabrics in modern landfills.

I. Core Functions: The Multiple Roles of Non-woven Geotextiles in Landfills

Landfill geotextiles are not simply a single-function material; rather, they are multifunctional products that combine isolation, filtration, drainage, and reinforcement.

High-Efficiency Isolation Layer:

Application Scenario: Used between the waste mass and the underlying soil, or between different functional layers (such as a gravel drainage layer and a soil layer).

Purpose: Environmentally friendly non-woven fabrics effectively prevent mixing of waste and soil, maintaining their structural and functional integrity and preventing contamination of the foundation soil. They are a crucial component of landfill anti-seepage systems.

Excellent filtration and backwashing capabilities:

Applications: Primarily used around leachate collection and drainage systems.

Purpose: When leachate flows through geotextile filter materials, engineering nonwovens prevent fine soil particles from entering the drainage pipes while ensuring smooth liquid flow, preventing drainage system blockage and ensuring long-term effective leachate drainage.

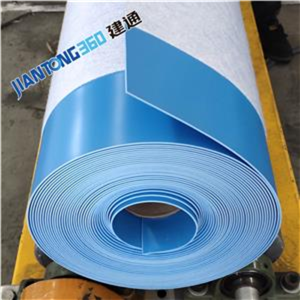

Horizontal drainage and gas diversion:

Applications: Layed at the bottom or in the cover layer of a landfill.

Purpose: Polyester or polypropylene nonwovens have a certain level of horizontal drainage capacity, assisting in the collection and drainage of leachate and biogas generated by waste decomposition, thereby enhancing the stability and safety of the landfill.

Reinforcement and protection:

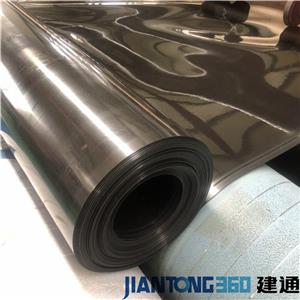

Applications: Used on slopes or final cover layers.

Purpose: High-strength geotextiles have a certain tensile strength, allowing them to bond with the soil, improving the overall stability of the slope. They also provide effective soft protection for underlying anti-seepage materials such as HDPE geomembranes, preventing them from being punctured by sharp objects.

II. Product Advantages: Why Choose a Professional Landfill Geotextile?

Excellent Physical Properties: High-quality needle-punched nonwoven fabric offers excellent longitudinal and transverse breaking strength and elongation, adapting to deformation of landfill foundations.

Chemical Resistance: Polypropylene nonwoven fabric is highly resistant to acids, alkalis, salts, and other chemicals commonly found in landfill leachate, ensuring long-term performance.

Excellent Water Permeability: The fluffy three-dimensional fiber structure ensures excellent water permeability, making it ideal for filtration and drainage.

Environmentally Compliant: As an environmentally friendly geotextile, it produces no harmful substances and meets environmental regulations for landfill construction.

III. Selection Guide: How to Choose the Right Nonwoven Geotextile for Landfills?

When choosing a nonwoven fabric specifically for landfills, focus on the following technical specifications:

Weight and Thickness: Select the appropriate specification (e.g., 600g geotextile, 800g geotextile, etc.) based on your project design requirements. Breaking Strength: Ensures it can withstand foundation stress and construction loads.

CBR Bursting Strength: Reflects its ability to resist rupture by sharp objects and is crucial for protecting the geomembrane.

Vertical Permeability: Directly related to its filtration and drainage efficiency.

In summary, non-woven geotextiles are no longer simply auxiliary materials; they are now one of the core geotechnical materials that ensure the long-term stable, safe, and environmentally friendly operation of landfills. Selecting engineering non-woven fabrics with reliable quality and matching performance is the foundation for the success of every landfill project. Our company's series of geotextile products strictly comply with national standards and are designed specifically for the stringent environmental engineering environments. We are your reliable partner in building high-standard landfills.