Traditional cement VS cement blanket

Traditional cement VS cement blanket

Characteristics and advantages of cement blanket

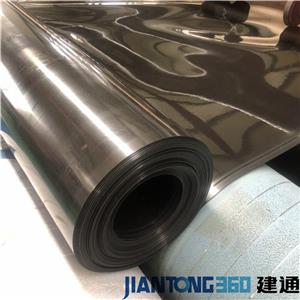

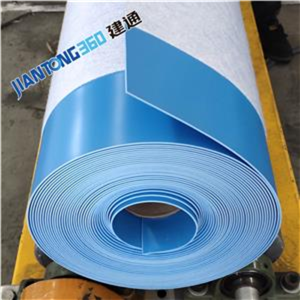

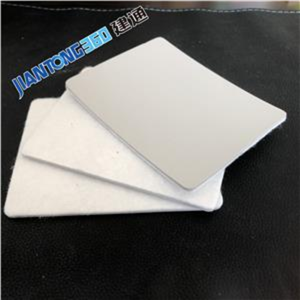

Cement blanket is a composite material composed of cement, water and fiber. Before encountering water, cement blanket is soft like a blanket, can be rolled up for transportation, and can be cut at will according to needs. Once encountering water, cement blanket will quickly undergo chemical reaction and become a solid concrete blanket. This characteristic gives cement blanket the following advantages:

1. Versatility: Cement blanket can be used in multiple engineering fields such as slope protection, hardening, waterproofing, etc., and has a wide range of applicability.

2. Lightweight and easy to transport: The soft characteristics of cement blanket make it easy to roll up and transport, reducing the dependence on large machinery and equipment.

3. Flexible and cuttable: Cement blanket can be cut at will according to actual needs to meet engineering requirements of various shapes and sizes.

4. Rapid curing: Cement blanket can quickly undergo chemical reaction after encountering water to form a solid concrete structure, greatly shortening the construction time.

5. Cost-effectiveness: The cost of cement blanket is half of that of traditional concrete, which is of great

significance for the budget control of engineering projects.

Disadvantages of ordinary cement: ① Concrete has low tensile strength and is not suitable for use as a tensile member ② Concrete has poor ability to resist deformation and is prone to cracking and brittle failure ③ Concrete has too much deadweight and volume, which brings great inconvenience to construction and use ④ Concrete has strong shrinkage, and the production process is complex and prone to quality fluctuations, and is prone to common quality problems such as cracks, missing edges, falling corners, rough surfaces, honeycombs, exposed reinforcement, etc.