The advantages of cement blankets

The advantages of cement blankets

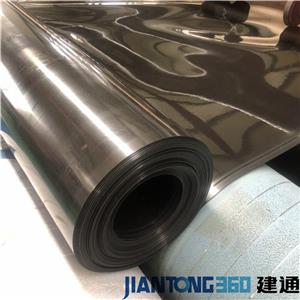

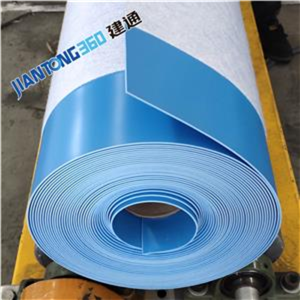

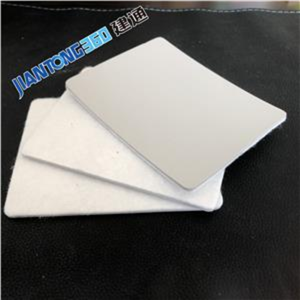

1.Compared with the use of traditional concrete, it mainly has the advantages of simple use, rapid solidification molding, environmental protection and flexible application. It can be provided in bulk, or can also be provided in bulk, convenient for manual loading and unloading and transportation, without large lifting machinery. Concrete is not prepared on site, and excessive hydration problems will not occur. Once the hydration reaction occurs, the concrete canvas can still be processed within 2 hours, and within 24 hours, it can be hardened to 80% strength within 24 hours. Can also be according to the special requirements of the user, using a special formula to achieve the purpose of rapid solidification or delayed solidification.

2. Cement blankets (flexible concrete) can use concrete in slopes, water and other hard-to-reach locations without form or mixing. Provide for both strength and durability. Make it an ideal option for strengthening or repairing culverts or drains, berms, or other structures. Once hydrated, the cloth quickly solidifies, creating a rigid, durable and waterproof 5,000 psi strength.

First, the preparation work

It is necessary to plan the plan in advance and measure it in advance to ensure that a certain slope can smooth the water flow from the top into the bottom.

It is necessary to clean up the construction ground, clean up the weeds, trees and garbage in the construction site, and then level off and repair the ground and slope surface, and retest the drainage slope.

Second, the site leveling construction

The slope, ground and ditch must be repaired and smooth, and the contact surface with the cement blanket should be strong without empty soil and hollow. For the parts prone to water damage, the gravel and debris on the slope should be removed to ensure that the parts are stable and reliable after treatment.

Third, the cement blanket laying

Surface cleaning: Before laying the cement blanket, the impurities, loose soil, stones and other pollutants on the ground and slope must be carefully removed to ensure the effective close bonding between the blanket and the ground.

Measurement and cutting: measure and cut the cement blanket according to the area needed to be laid. In general, you can be cut using knives or serrations.

Fixed edge: fix the edge of the cement blanket to the ground (slope) with 6mm U-shaped nails and tile nails to prevent the blanket from moving or dispersing. In the reinforcement and fixation, the edges of the cement blanket should be rolled to ensure the overall beauty.

Laying cement blanket: spread the cement blanket on the ground, and use a roller or compaction equipment to flatten the blanket to make it closely combined with the ground.

Fourth, the joint treatment

When laying the cement blanket, the joint treatment of the two adjacent cement blankets is very important. The specific steps are described as follows:

1. Dig a hole 10 cm wide and twice the depth of the cement blanket at the stack of two adjacent cement blankets.

2. Put the cement blanket joint at the stack into the pit and level it. Make sure that the two superimposed cement blankets are not less than 10 cm.

3. Connect the cement blanket with tile nails at the joints to ensure that the connection between the cement blankets is close.

4. Fixed two cement blankets with 6mmU stainless nail to ensure that the cement blanket does not shift or separate.

Fifth, maintenance after the shop watering

Watering 2-3 times, more than 10 kg specification cement blanket watering 3-4 times, 12 hours interval pouring once. Stand and wait, and the general setting time is 48-72 hours.