Key Applications of Geomembranes and Geotextiles in Landfills: An Industry Breakthrough in Environmentally Friendly Seepage Control Technology

Recently, with the continued advancement of environmental protection policies, landfill anti-seepage projects have become a focus of industry attention. As key components of geosynthetics, geomembranes (HDPE geomembranes, composite geomembranes) and geotextiles (short-filament geotextiles, filament geotextiles) are increasingly used in landfills, providing efficient solutions for anti-seepage, isolation, and reinforcement.

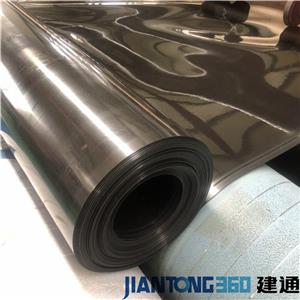

Geomembranes: The "Anti-Seepage Guardian" of Landfills

In landfill construction, high-density polyethylene geomembranes (HDPE geomembranes) have become a core material for anti-seepage systems due to their excellent chemical resistance, high tensile strength, and low permeability. Using hot-melt welding technology, geomembranes can form a continuous, seamless anti-seepage layer, effectively preventing leachate from contaminating groundwater and soil. Furthermore, roughened geomembranes, with their enhanced friction coefficient, excel in slope anti-seepage projects, significantly improving landfill stability.

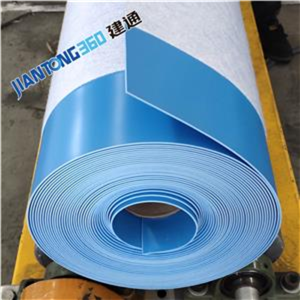

Geotextiles: A Key Role as a Multifunctional Protective Layer

As a supplementary material to geomembranes, needle-punched nonwoven geotextiles perform filtration, drainage, and protection functions in landfills. In anti-seepage systems, geotextiles are typically laid above and below geomembranes, providing a buffering and protective layer to prevent sharp objects from piercing the anti-seepage layer. Polyester and polypropylene geotextiles, with their excellent permeability and aging resistance, are widely used in leachate drainage layers, ensuring the long-term stability of landfill drainage systems.

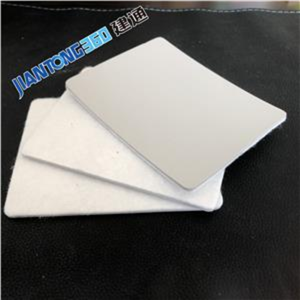

Industry Trends: Geocomposite Materials and Green Construction Techniques

With technological advancements in the geotechnical industry, composite geomembranes (two geomembranes, one geomembrane, or one geomembrane) are becoming the preferred choice for landfill projects due to their ease of installation and superior overall performance. Furthermore, the combination of GCL bentonite waterproofing blankets and geomembranes further enhances the reliability of anti-seepage systems. In terms of construction technology, the introduction of automated laying equipment and non-destructive testing technologies has significantly improved project efficiency and quality control.

Industry experts indicate that with the advancement of "zero-waste cities" construction, the application of geosynthetics in solid waste management will become even more widespread. Growing demand in applications such as anti-seepage projects, slope reinforcement, and tailings management will further drive the research and development and application of new geotechnical materials such as geogrids, geocells, and three-dimensional drainage nets.

The successful implementation of this landfill project not only demonstrates the important role of geomembranes and geotextiles in environmental protection projects but also provides the industry with a replicable technical solution, helping my country's ecological civilization development reach new heights.

Keywords: geomembrane, HDPE geomembrane, composite geomembrane, geotextile, short-filament geotextile, long-filament geotextile, anti-seepage project, landfill, leachate, GCL bentonite waterproofing blanket, geogrid, geosynthetics, environmental protection project, hot-melt welding, zero-waste city