In-depth analysis of LDPE and HDPE geomembranes: How to accurately select materials for engineering waterproofing?

In modern civil engineering, environmental protection, and water conservancy construction, geomembranes are indispensable "impermeable guardians." However, with the wide variety of products on the market, choosing the most suitable material for project needs is often challenging. Among them, LDPE geomembranes (low-density polyethylene) and HDPE geomembranes (high-density polyethylene) are the two most widely used types.

Although both belong to the polyethylene family, they differ significantly in performance and application scenarios. This article will provide an in-depth analysis of the advantages and disadvantages of both, helping you make informed decisions.

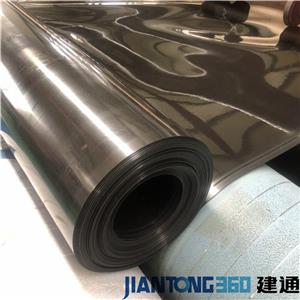

I. HDPE Geomembrane: The "Hardcore Armor" of Impermeable Engineering

HDPE geomembrane, commonly known as "high-density polyethylene film," is renowned as the "tough guy" of impermeable engineering due to its excellent chemical stability and high strength.

✅ Core Advantages

1. **Extremely strong chemical resistance**

HDPE has excellent resistance to acids, alkalis, salts, and organic solvents. In harsh environments such as chemical plants and landfills, it can maintain stability for a long time, making it the preferred choice for handling toxic and hazardous substances.

2. **High mechanical strength and puncture resistance**

It has high tensile strength and hardness, effectively resisting punctures from sharp stones. In high-stress environments (such as steep slopes and deep pits), it is not easily deformed or broken.

3. **Extremely low permeability**

Its molecular structure is compact, and its permeability coefficient is extremely low, making it one of the most reliable liquid barrier materials currently available.

4. **Wide temperature range**

It can maintain stable performance at extreme temperatures from -60℃ to +60℃, adapting to various harsh climates.

#### ❌ Limitations

- **Poor flexibility**: The material is relatively hard, requiring a very high degree of flatness of the base surface during installation, making it difficult to adapt to complex terrain deformations.

- **Weak UV resistance**: Long-term exposure to sunlight can easily cause aging, and a protective layer (such as soil or non-woven fabric) is usually required. #### ?️ Applicable Scenarios

- Landfills (landfill pits, capping and covering)

- Wastewater treatment ponds, chemical reaction tanks

- Hazardous materials warehouses, tailings dams

- Large reservoirs and drinking water reservoirs

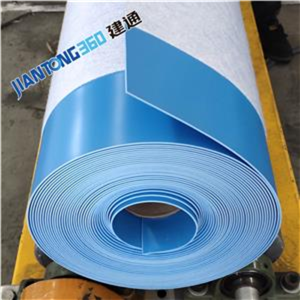

### II. LDPE Geomembrane: The Flexible, Impermeable "Close Protector"

LDPE geomembrane, or "low-density polyethylene membrane," is more like a soft "close protector" compared to HDPE.

#### ✅ Core Advantages

5. **Excellent Flexibility and Ductility**

LDPE has a high degree of branching in its molecular chains, resulting in a soft texture and high elongation. It can conform well to uneven surfaces, adapt to foundation settlement and deformation, and is very easy to install.

6. **Excellent Low-Temperature Resistance**

Even at extremely low temperatures (can withstand -70℃), it remains soft and does not become brittle, making it suitable for projects in cold regions.

7. **Easy Processing and Welding**

It has a lower processing temperature and good fluidity, making it easy to produce films of various thicknesses, and heat welding is relatively easy.

8. **Cost Advantage**

Compared to HDPE, LDPE generally has lower production costs, making it an economical choice for budget-sensitive projects.

#### ❌ Limitations

- **Lower Strength and Hardness**: Its tensile strength and puncture resistance are not as good as HDPE, and it is easily scratched by sharp objects.

- **Poor Heat Resistance**: It has a lower softening point, and the long-term use temperature generally does not exceed 60℃; it is prone to softening and deformation at high temperatures.

- **Slightly Weaker Impermeability**: Its air and moisture permeability is higher than HDPE, so it may not be the best choice for applications requiring extremely high airtightness and impermeability. #### ?️ Applicable Scenarios

- Agricultural irrigation canals and reservoirs

- Artificial lakes and landscape ponds (requiring high adaptability to terrain)

- Greenhouses and temporary waterproof coverings

- Cable sheathing and packaging films

### ? III. At a Glance: Core Parameter Comparison of LDPE vs. HDPE

To help you quickly differentiate between them, we have compiled the following comparison table:

| Characteristic | HDPE (High-Density Polyethylene) | LDPE (Low-Density Polyethylene) |

| ------ |------ |------ |

| **Feel and Appearance** | Stiff, rigid, translucent/opaque | Soft, easily deformable, higher transparency |

| **Tensile Strength** | ⭐⭐⭐⭐⭐ (Extremely High) | ⭐⭐⭐ (Medium) |

| **Puncture Resistance** | ⭐⭐⭐⭐⭐ (Extremely Strong) | ⭐⭐ (Weak) |

| **Flexibility/Ductility** | ⭐⭐ (Poor) | ⭐⭐⭐⭐⭐ (Excellent) |

| **Chemical Resistance** | ⭐⭐⭐⭐⭐ (Excellent) | ⭐⭐⭐⭐ (Good) |

| **Heat Resistance** | ⭐⭐⭐⭐⭐ (Good, high temperature resistant) | ⭐⭐⭐ (Poor, low temperature resistant) |

| **Main Disadvantages** | Susceptible to environmental stress cracking, high installation requirements | Low mechanical strength, not high temperature resistant |

### ? IV. Expert Advice: How to Choose?

- **Choose HDPE if your project:**

- Needs to resist strong acids, strong bases, and other chemical corrosion.

- Faces environments with many sharp objects and high pressure (such as landfills).

- Requires an ultra-long service life of 50 years or more.

- Has a sufficient budget and seeks the ultimate waterproofing effect.

- **Choose LDPE if your project:**

- Has complex terrain and uneven surfaces, requiring the material to conform closely.

- Is mainly used for water body waterproofing (such as fish ponds, canals), and there is no strong chemical corrosion.

- Needs to be constructed in extremely cold environments, requiring the material not to become brittle.

- Seeks cost-effectiveness and is a short-term or medium-term project. **About [Your Website Name]**

[Insert your company profile or website description here, for example: We specialize in providing high-quality geosynthetic material solutions, with many years of industry experience, and are committed to providing reliable anti-seepage products for environmental protection, water conservancy, transportation, and other fields.]