HDPE geomembrane vs PVC geomembrane: ideal choice for different project types

Introduction: In various civil engineering, environmental engineering and water conservancy projects, geomembranes, as an important anti-seepage material, play a key role. HDPE (high-density polyethylene) geomembranes and PVC (polyvinyl chloride) geomembranes are two commonly used materials, each with different characteristics and suitable for different engineering scenarios. This article will introduce their characteristics and applicable engineering types in detail to help you make a more reasonable choice.

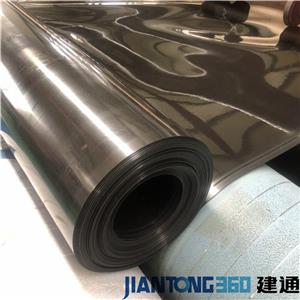

Characteristics and applicable engineering of HDPE geomembranes

Characteristics

High strength and puncture resistance: HDPE geomembranes have high tensile strength and tear resistance, suitable for high-load engineering.

Excellent chemical corrosion resistance: It can resist the erosion of acids, alkalis, oils and various chemical substances, and is suitable for chemical, landfill and other environments.

Good UV resistance: Long service life in open air environment, not easy to age.

Low temperature adaptability: It can still maintain good flexibility in cold areas.

High anti-seepage performance: The permeability coefficient is extremely low and the anti-seepage effect is excellent.

Applicable engineering types

Landfill: Corrosion resistance, anti-leakage, prevent pollutants from seeping into groundwater.

Sewage treatment pool: chemical corrosion resistance, long-term stable operation.

Water conservancy projects (reservoirs, channels): high strength, water pressure resistance, suitable for large-scale anti-seepage projects.

Mine tailings pond: puncture resistance, wear resistance, prevent leakage of harmful substances.

Petrochemical anti-seepage: oil resistance, chemical resistance, ensure safe storage.

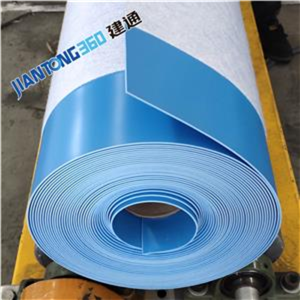

Characteristics and applicable projects of PVC geomembrane

Characteristics

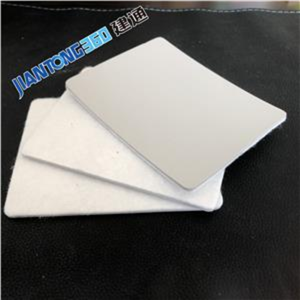

Flexibility and easy construction: PVC geomembrane is soft, easy to lay and weld, suitable for complex terrain.

Good elongation: adapt to foundation deformation and reduce the risk of cracking.

Resistance to microbial erosion: suitable for humid and bacteria-prone environments.

Economical: low cost, suitable for projects with limited budgets.

Customizable colors (such as black, green, etc.), suitable for landscape projects.

Applicable project types

Artificial lakes, landscape pools: good flexibility, easy to shape, beautiful and practical.

Roof garden anti-seepage: lightweight, easy to lay, protect building structures.

Agricultural reservoirs and breeding ponds: resistant to microorganisms, environmentally friendly and safe.

Waterproofing of tunnels and subways: adapt to structural deformation and reduce the risk of leakage.

Temporary anti-seepage projects: convenient construction, economical and efficient.

How to choose a suitable geomembrane?

Consider the engineering environment: If the chemical corrosion is strong, HDPE is preferred; if flexibility is required, PVC can be selected.

Budget factors: PVC has a lower cost and is suitable for small and medium-sized or short-term projects; HDPE has better long-term performance and is suitable for large and high-standard projects.

Construction conditions: PVC is recommended for complex terrain, while HDPE is recommended for high-load projects.

Conclusion

HDPE and PVC geomembranes have their own advantages. Choosing the right material can significantly improve the quality and durability of the project. We provide HDPE and PVC geomembranes in various specifications, and can customize solutions according to project needs. For further consultation, please contact our professional team and we will provide you with the best solution!