Composite geomembrane of geotechnical materials used in the repair and seepage prevention work of tailings pond

With the gradual strengthening of the national awareness of environmental protection, the construction of tailings landfill has put forward higher requirements. The traditional anti-seepage method, cement concrete, stone stacking, waterproof coating and so on are no longer applicable, accompanied by the rapid development of geosynthetic materials, and widely used in various fields. Geosynthetics are divided into four categories: geotextile, geomembrane, geotechnical composite materials and geotechnical special materials, among which new HDPE geomembrane, geotextile, composite geomembrane, bentonite waterproof blanket, composite drainage network and other geotechnical materials are also more and more common in the mine tailings pond environment. They play an important role in the tailings repair and seepage prevention work with their excellent seepage prevention performance, construction convenience and excellent durability.

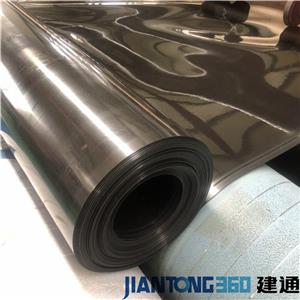

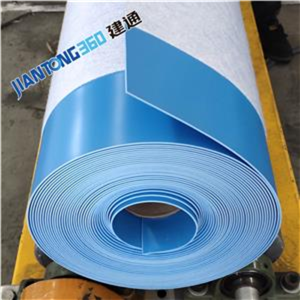

Today we share the geotechnical material ——— composite geomembrane。

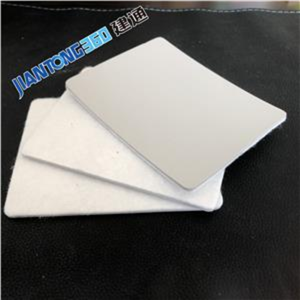

Composite geomembrane is with geotextile and geomembrane composite impermeable material, it is mainly used for seepage prevention, composite geomembrane is divided into a cloth and two cloth membrane, with tensile, tear resistance, physical and mechanical properties, can meet water conservancy, municipal, construction, transportation, subway, tunnel, engineering construction of seepage control, isolation, reinforcement, crack and civil engineering needs. It is often used for anti-seepage treatment of DAMS and drainage ditches, and for anti-fouling treatment of waste yards. Specification: two cloth and one film: cloth 100g-600g / m2, film thickness: 0.2mm-0.8mm. One cloth and one film: cloth: 100g-600g / m2, membrane thickness: 0.25mm-15mm.